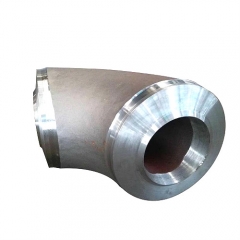

ASME Standard Power Plant Steam Boiler Manifold Headers

Hot Products

ASME Standard Power Plant Steam Boiler Manifold Headers

Performance advantage

The key to the manufacture of the header is the welding of the end cap (or head). When welding, most manufacturers use manual arc welding, because the weld is single-sided welding, the root quality is difficult to guarantee, and because of the huge of welding work, number of repairing times, the production cycle is long which cause the entire production process slow. Our company adopt the advanced production technology, well-equipped instrument and sophisticated technology, and invented a submerged arc welding method during the header and cover welding. The character is: In the submerged arc welding machine head threading mechanism fixed connection welding wire guide, along the wire guide head to set the wire guide hole, the wire lead head has a certain degree of curvature, welding the inner wall, the wire guide head extension Into the inside of the welding. The welding method mainly solves the problem that the existing welding method of the boiler header and the end cap (or the head) has the advantages of low processing efficiency, waste of argon at the time of processing, need to open the groove, have many processes, high processing cost and unsatisfactory welding fabrication.

Packaging & Delivery

Packaging Details: standard export packaging (as per customer's specification)

Delivery Details: Within 15-30 days

Product Desciption

1. Size: Customized Size

2. Material: AISI304

3. Finish: Mirror polish, Matt polish

4. Connection: Welded, Clamped

5. Packaging: Shrink packed – carton -plywood case if need

6. Sample: Sample and freight cost can be negotiable

7. Applications: Pharmacy, beer, food, dairy, brewing, beverage, water treatment and chemical industry

The key to the manufacture of the header is the welding of the end cap (or head). When welding, most manufacturers use manual arc welding, because the weld is single-sided welding, the root quality is difficult to guarantee, and because of the huge of welding work, number of repairing times, the production cycle is long which cause the entire production process slow. Our company adopt the advanced production technology, well-equipped instrument and sophisticated technology, and invented a submerged arc welding method during the header and cover welding. The character is: In the submerged arc welding machine head threading mechanism fixed connection welding wire guide, along the wire guide head to set the wire guide hole, the wire lead head has a certain degree of curvature, welding the inner wall, the wire guide head extension Into the inside of the welding. The welding method mainly solves the problem that the existing welding method of the boiler header and the end cap (or the head) has the advantages of low processing efficiency, waste of argon at the time of processing, need to open the groove, have many processes, high processing cost and unsatisfactory welding fabrication.

Packaging & Delivery

Packaging Details: standard export packaging (as per customer's specification)

Delivery Details: Within 15-30 days

Product Desciption

1. Size: Customized Size

2. Material: AISI304

3. Finish: Mirror polish, Matt polish

4. Connection: Welded, Clamped

5. Packaging: Shrink packed – carton -plywood case if need

6. Sample: Sample and freight cost can be negotiable

7. Applications: Pharmacy, beer, food, dairy, brewing, beverage, water treatment and chemical industry

pipe fittings